In the field of diagnostic applications, precision, reliability and good quality management are essential. With more than 30 years of experience in the diagnostic field, Lohmann is a reliable partner for the medical industry. Depending on the requirements, proven standard products are available or innovative custom products are developed - precisely tailored to the needs of the customer.

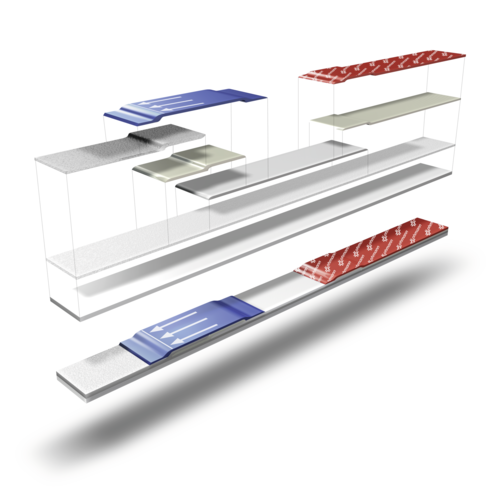

Lohmann's functional high-end adhesive tapes and die-cuts meet the tightest process tolerances, are stable and easy to process, as well as non-reactive and non-migrating. Adhesive tapes for biosensor applications are made of inert materials, contributing to a high level of patient protection. By assay-protecting sealing in microfluidic applications (lab-on-a-chip) or water-repellent coating of the carrier materials, among others in lateral flow applications (e.g. Corona tests, blood glucose tests, urine samples), the adhesive tapes ensure accurate results, both in medical laboratories and in private households.

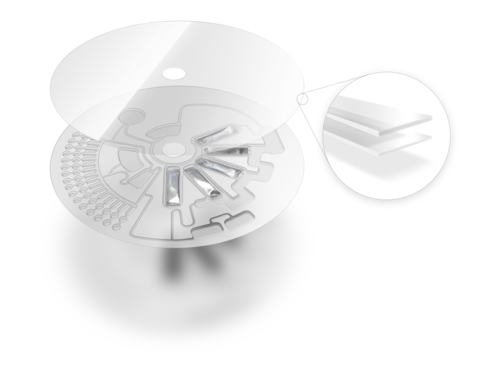

Lab-on-a-Chip

Your benefits:

As one of the market leaders, Lohmann‘s Bonding Engineers formulate, manufacture, coat and die-cut high-precision adhesive solutions for clinical and diagnostic products. This extensive knowledge of adhesive tape development combined with comprehensive die-cutting capabilities shortens our customer‘s development cycles and increases flexibility in their production processes.

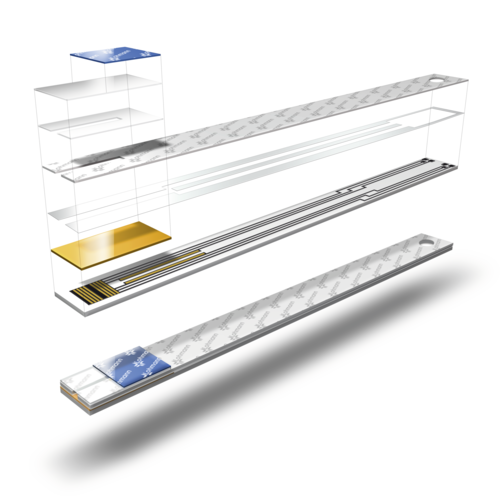

With the latest design of a Lateral Flow Test Strip with new eco-friendly backing material, there is the perfect combination of the highest quality standards for lateral flow devices with sustainable components. By using renewable materials and implementing an efficient manufacturing process the environmental impact is reduced an circularity possible without compromising quality or safety.

Your benefits:

Lateral Flow

Your benefits:

From the initial idea to the implementation into the final process – from prototyping to series production – Lohmann produces customer-specific adhesive tapes and converts them into die-cuts. Directly from one source, independently from intercontinental supply chains, in various high-precision manufacturing processes (e.g., laser plotter, rotary die-cutting, etc.) and in low μm-tolerances.

Benefit from Lohmann's converting network with numerous locations in Europe, America and Asia. With state-of-the-art coating, converting and die-cutting lines as well as technology centers, the experts in Lohmann's sites worldwide offer you all their know-how in the production and assembly of your individual adhesive solutions and advise you on site.

The whole product portfolio of single- and double-sided adhesive tape solutions is available on rolls, spools, as die-cuts or sheets. Lohmann provides customized solutions in a wide variety of materials that combine the individually required properties.

Interested in finding out more?

Then contact us. We will be pleased to help.

Contact form Medical

For further information or your enquiries, please send us an email. We look forward to hearing from you!